Press release -

Verify the load-bearing capacity for pile foundations comprehensively and reliably

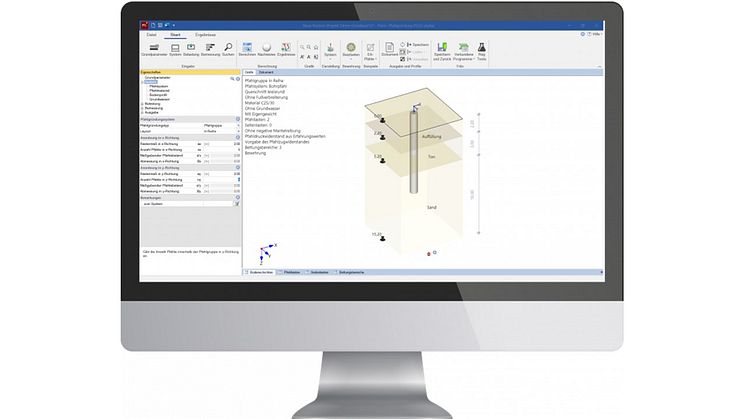

Stuttgart, February 3, 2022 - If soil or rock layers with insufficient load bearing capacity have to be bridged in the subsoil during construction work, pile foundations are used. To make sure that the piles provide a safe foundation for supporting structures complex requirements, such as the non-linear resistance-settlement curve, and special foundation-specific actions must be considered. The FRILO programme Pfahl+ takes all these requirements relating to pile foundations into account.

In a construction project, pile foundations are usually needed if the subsoil near the surface has insufficient load-bearing capacity. As a result, piles are drilled or driven into the subsoil to transfer loads from supporting structures to deeper, load-bearing soil or rock layers. Once a layer with a satisfactory load-bearing capacity has been reached at depth, special structural challenges have to be overcome in the dimensioning and verification of the piles used. The Pfahl+ programme, newly developed by FRILO, provides for reliable verification of the internal and external load-bearing capacity of drilled piles with rectangular or circular cross-sections.

Negative skin friction and lateral earth pressure definable as actions

The friction that occurs between the soil and the pile is caused by relative deformations between the soil and the pile shaft. It is referred to as skin friction. If the soil around the pile shaft experiences greater settlement than the pile itself, this is referred to as negative skin friction. With reverse conditions, there is positive skin friction. Because the negative skin friction is to be considered as a permanent action according to the partial safety concept, it produces an additional stress component. By comparing the pile settlements to the soil settlements along the pile skin surface, an action from negative skin friction up to the neutral point can be optionally applied.

Soil displacements in soft cohesive soil also produce actions transverse to the pile axis. The lateral earth pressure to be applied is derived either from the flow pressure or from an earth pressure difference. In each case, the smaller one of the resulting total forces is decisive. Thanks to the direct connection to the proven FRILO programmes Soil Settlement (SBR+) and Earth Pressure Calculation (EDB+), both the soil settlements in the pile surroundings (and thus the negative skin friction) and the lateral earth pressure acting on the piles can be automatically taken into account.

Verification of vertical load transfer via skin friction and end-bearing pressure

The verification of the external load-bearing capacity of the pile in the vertical direction is performed for pile foundations considering the positive skin friction and the end-bearing pressure of the piles. Positive skin friction is the friction that occurs between the subsoil and the pile along the surface of the pile when pressure is applied from above. The remaining compressive forces act on the toe of the pile. The axial pile resistances, which can be mapped via non-linear resistance-settlement curves and which result from skin friction and end-bearing pressure, can optionally be derived by evaluating static or dynamic pile test loads separately for the serviceability limit state (SLS) and the ultimate limit state (ULS). Alternatively, a derivation of the resistance-settlement curve based on empirical values given by the recommendations of the pile work group “Arbeitskreis Pfähle” is possible. For a resulting tensile load in the pile, the axial pile resistances from skin friction are verified analogously. For tension piles, the verification of the safety against uplift (UPL) is optionally performed with the help of an attached soil prism.

Verification of the horizontal load transfer via the subgrade reaction

The subgrade reaction modulus method is used to check the external pile load-bearing capacity in the horizontal direction. For this purpose, subgrade reaction regions can either be derived from the soil stratification or be defined by the user. The resulting horizontal stresses must not exceed the maximum earth resistance stress at any point. If necessary, the subgrade reaction regions must be adjusted after the first calculation in order to redistribute the horizontal stresses to greater depths if the limit condition is exceeded.

Design calculation

In order to verify the internal load-bearing capacity, the reinforced concrete cross-sections are designed on the basis of a non-linear calculation. In this calculation, the second-order additional loads and the actual pile stiffnesses due to freely selectable reinforcement are taken into account. As a result, the required bending and shear reinforcement quantities are output.

Topics

Categories

About the Nemetschek Group

The Nemetschek Group is a pioneer for digital transformation in the AEC/O and the media & entertainment industries. With its intelligent software solutions, it covers the entire lifecycle of building and infrastructure projects, guides its customers into the future of digitalization and enables them to shape the world. As one of the leading corporate groups worldwide in this sector, the Nemetschek Group increases quality in the building process and improves the digital workflow for all those involved. Customers can design, build, and manage buildings more efficiently, sustainably and resource-saving. The focus is on the use of open standards (OPEN BIM). The portfolio also includes digital solutions for visualization, 3D modeling, and animation. The innovative products of the 13 brands of the Nemetschek Group in the four customer-oriented segments are used by approximately 6.5 million users worldwide. Founded by Prof. Georg Nemetschek in 1963, the Nemetschek Group today employs around 3,400 experts all over the world.

Publicly listed since 1999 and quoted on the MDAX and TecDAX, the company achieved revenue amounting to EUR 596.9 million and an EBITDA of EUR 172.3 million in 2020.